Introduction

The boron element, a metalloid with atomic number 5, stands out in the periodic table element boron for its unique ability to form strong covalent bonds. It occupies a niche between metals and non-metals, making it indispensable in fields from agriculture to high-tech industries. Its scarcity in the Earth’s crust, at just 0.001%, contrasts with its critical role in modern applications. Boron’s versatility stems from its chemical flexibility and physical resilience. This article explores its properties, diverse uses, production processes, sustainability challenges, and future potential. It highlights why the boron element is a cornerstone of scientific and industrial progress.

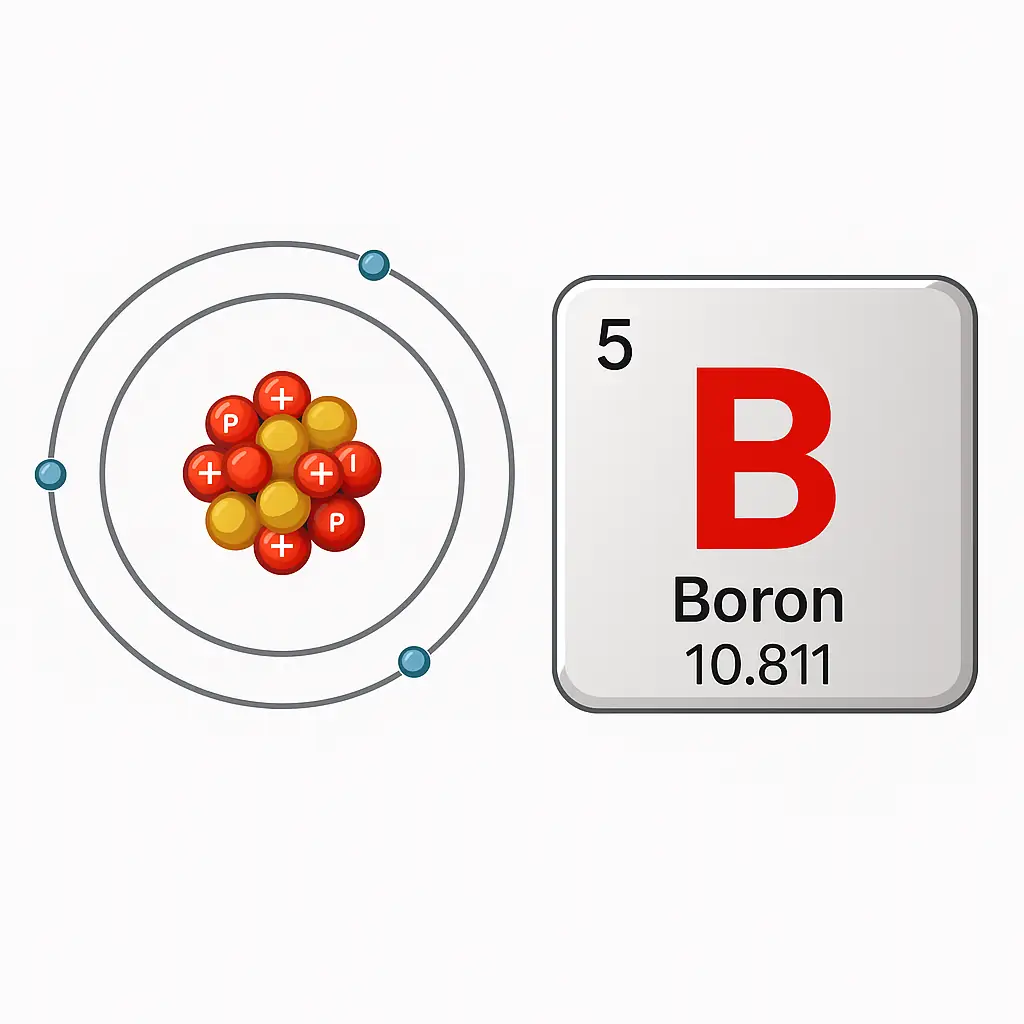

Chemical and Physical Properties

The boron element exhibits remarkable chemical and physical traits. Its symbol, known as the boron element symbol, is B, with an atomic mass of about 10.81 u. Boron appears in two forms: a dark, crystalline solid or an amorphous brown powder. Its hardness approaches that of diamond, making it exceptionally durable. The boron element charge is neutral in its elemental state, but it forms a +3 ion by losing three electrons in compounds like boron trifluoride (BF₃). Its electron configuration, 1s² 2s² 2p¹, allows it to create stable covalent bonds, often forming complex molecules like boranes. Boron’s melting point is 2,076°C, and its thermal conductivity is high. It resists corrosion due to a protective oxide layer. These properties enable its use in extreme conditions, from high-temperature reactors to abrasive tools. Boron’s low density, about 2.34 g/cm³, adds to its appeal in lightweight materials. Its unique bonding also leads to semiconductor properties, crucial for electronics.

Key Applications

The boron element is a powerhouse across industries, driven by its chemical versatility. In agriculture, boron is a vital micronutrient. Borax and boric acid enhance crop growth by supporting cell wall formation and nutrient uptake. This is critical for fruits, vegetables, and grains. Deficiency in boron can reduce yields by up to 20%, especially in soils of regions like South Asia. The periodic table element boron also excels in materials science. Boron nitride, with a structure similar to graphite or diamond, is used in cutting tools and heat-resistant coatings. Borosilicate glass, containing 10–15% boron oxide, resists thermal shock. It is widely used in laboratory glassware, cookware, and even spacecraft windows. In nuclear energy, boron’s high neutron absorption makes it ideal for control rods and shielding. It helps regulate fission in reactors, enhancing safety. Boron-doped silicon improves the efficiency of solar panels and microchips. Boron fibers, stronger than steel yet lighter, reinforce composites in aerospace, such as aircraft wings and satellite frames. Emerging applications include boron-based nanomaterials for drug delivery and hydrogen storage, showing its potential in medical and energy sectors. These diverse uses underscore boron’s transformative impact.

Extraction and Processing

Extracting the boron element is a complex, energy-intensive process due to its rarity. Boron constitutes only 0.001% of the Earth’s crust, primarily found in borate minerals like borax, kernite, and ulexite. Major deposits are located in Turkey, which supplies 70% of global boron, followed by the United States and Chile. The process begins with open-pit or underground mining. Miners crush the ore and treat it with sulfuric acid to produce boric acid. This intermediate is refined into pure boron via reduction with magnesium or hydrogen at high temperatures. For high-purity boron, used in semiconductors, additional steps like zone refining are required. These processes consume significant energy, with estimates of 15–20 kWh per kilogram of refined boron. Water usage is also high, especially in arid mining regions. Historical extraction began in the 19th century with borax mining in California’s Death Valley, initially for soap production. Today, advanced hydrometallurgical techniques aim to reduce energy and water demands. However, scaling these methods is costly. Recycling boron from industrial waste, such as glass or ceramics, is being explored but remains limited due to technical challenges.

Challenges and Sustainability

Producing the boron element poses environmental, health, and economic challenges. Mining disrupts ecosystems, particularly in sensitive desert regions. Waste from borate processing, including tailings, can contaminate soil and water if not managed properly. Water-intensive extraction strains resources in arid areas like Turkey’s Anatolia region, where groundwater levels have dropped by 10–15% near mines. Energy demands for refining contribute to carbon emissions, with some facilities emitting 2–3 tons of CO₂ per ton of boron. Worker safety is a concern. Prolonged exposure to boron dust can cause chronic respiratory issues, necessitating strict protective measures. The boron element’s supply chain is vulnerable due to its concentration in a few countries. Turkey’s dominance raises risks of price volatility or export restrictions, especially amid geopolitical tensions. Recycling boron is inefficient, recovering less than 10% of used material. Research into sustainable practices is growing. For example, solvent extraction methods could reduce water use by 30%. Alternative materials, like carbon-based composites, may lessen reliance on boron in some applications. Public-private partnerships are funding pilot projects for greener boron production, but widespread adoption is years away. Addressing these challenges is critical for sustainable use.

Leave a Reply