Introduction

Cement is a vital construction material, binding materials like bricks and concrete. Used in structures from skyscrapers to sidewalks, it is essential for modern infrastructure. Cement production is a global industry, manufacturing billions of tons annually to support urbanization. Its development has enabled stronger, taller buildings, transforming construction practices. However, cement also poses environmental and health challenges that require attention.

This article examines cement’s role, benefits, and challenges in construction. It explores its historical evolution, production methods, and practical applications. Cement’s advantages, such as durability, are weighed against its environmental impact. Understanding cement’s significance provides insight into its contributions and limitations. Consider how this material shapes the built environment daily.

History of Cement

Cement’s history dates back thousands of years, predating modern industry. Ancient Egyptians used gypsum mixtures for pyramids, while Romans developed lime-based cement. Roman cement, mixed with volcanic ash, hardened underwater, enabling durable aqueducts and the Colosseum. These structures demonstrate cement’s early durability and versatility. This cement history highlights early engineering achievements.

By the Middle Ages, cement techniques declined, with weaker materials dominating. The 18th century saw renewed interest in stronger binders. In 1824, Joseph Aspdin patented Portland cement, made by heating limestone and clay. This innovation standardized cement production and supported modern construction. Portland cement remains the industry standard today.

Cement history reflects ongoing advancements tailored to modern needs. From Roman harbors to urban infrastructure, cement has enabled robust construction. Each development improved strength and versatility for diverse projects. This evolution underscores cement’s enduring role in shaping civilizations. Its historical significance continues to influence contemporary building practices.

Composition and Production

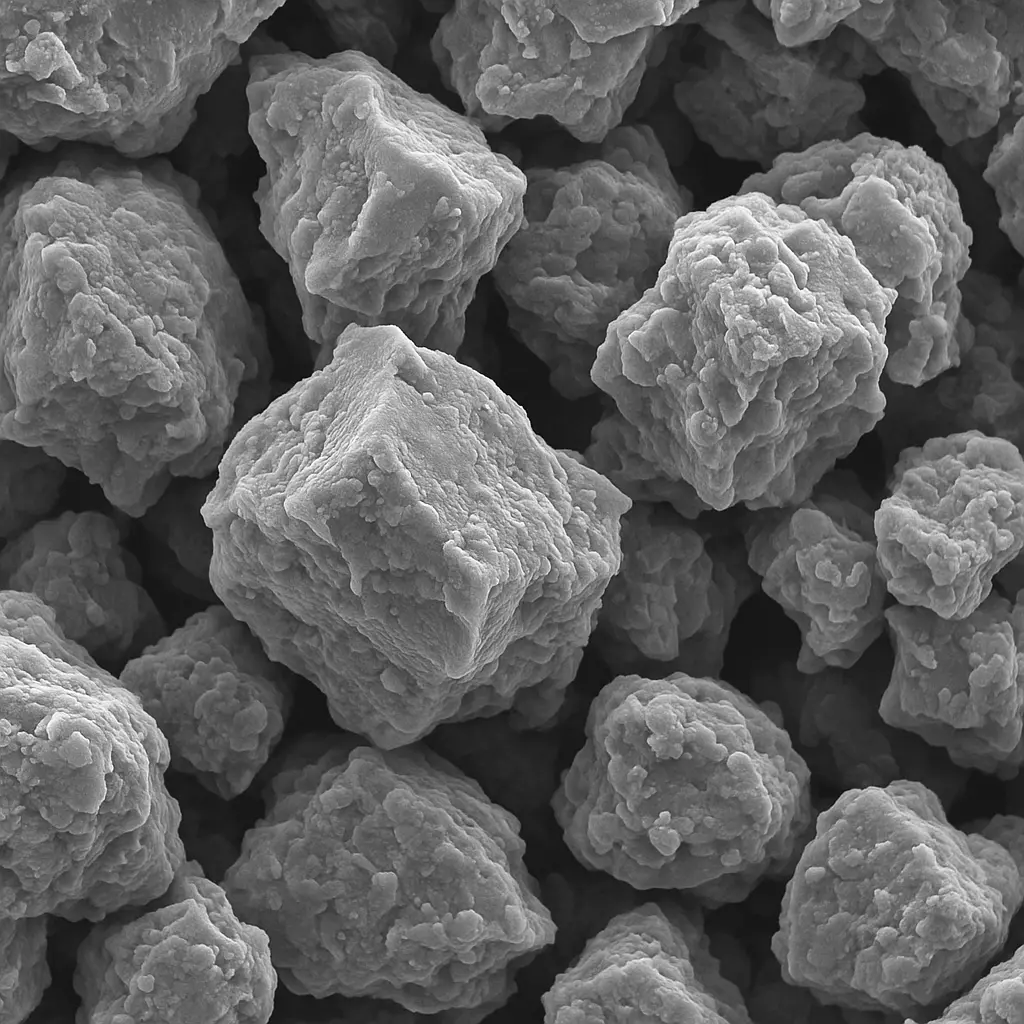

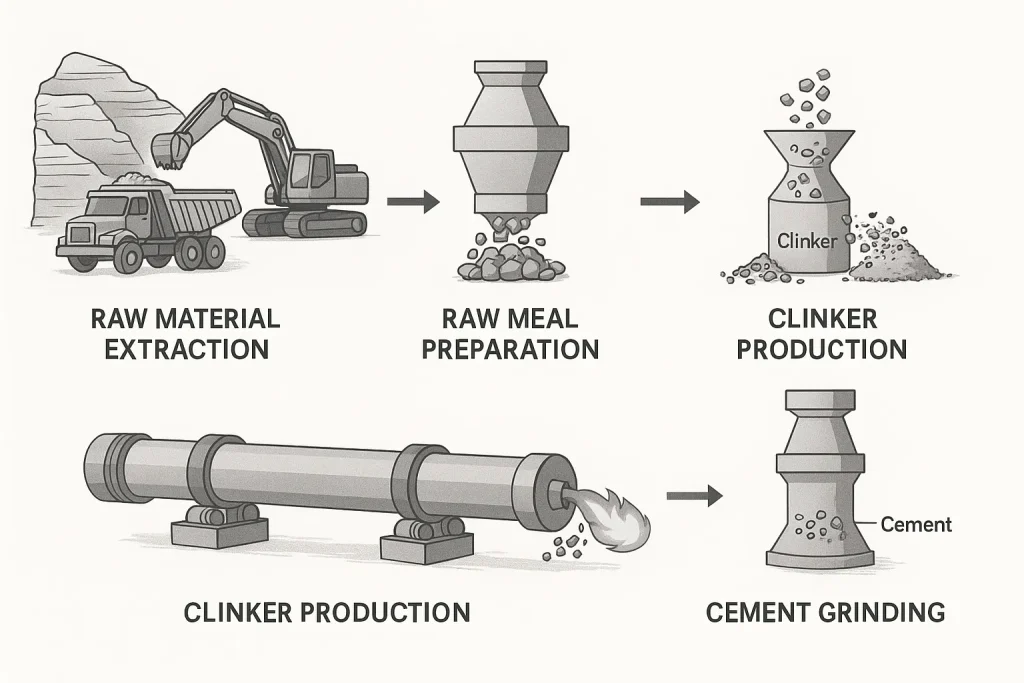

Cement production begins with raw materials like limestone, clay, and silica. These are crushed into a fine powder and heated in kilns at 1,450°C. This forms clinker, a rocky material ground with gypsum to produce cement. The process requires precise control to ensure quality. Cement production supports the creation of concrete and mortar globally.

Various cement types meet specific construction needs, such as rapid-setting or heat-resistant blends. Portland cement, containing 60–67% calcium oxide, is most common, while slag cement uses industrial byproducts. Adjusting ingredients, like adding fly ash, alters properties like strength. Cement production adapts to regional demands, ensuring suitability for diverse projects, from roads to buildings.

Cement production is a complex process combining chemistry and engineering. Kilns, often massive, rotate to heat raw materials evenly, producing clinker. The process consumes significant energy, often from fossil fuels, and generates dust, requiring filtration. Safety measures protect workers from dust exposure. This intricate system delivers cement for countless construction applications.

The hydration reaction drives cement’s functionality, as calcium silicates react with water. This forms a solid matrix that binds aggregates in concrete. Factories optimize this chemistry for local conditions, like freeze-thaw cycles. Cement production blends tradition with modern technology to meet global needs. Its chemical precision ensures reliable performance in construction.

Benefits of Cement

Cement benefits construction with exceptional strength and durability. As a key component of concrete, it supports structures like bridges and dams against natural forces. Its ability to set in wet conditions suits underwater projects, such as piers. Cement’s robustness ensures long-lasting infrastructure. These qualities make it indispensable for modern construction.

Cost-effectiveness is another key advantage of cement benefits. Cement is affordable to produce, and its durability reduces maintenance costs. Concrete roads, for instance, outlast asphalt, saving long-term expenses. Cement’s fire resistance enhances building safety, protecting occupants. Its widespread availability, using common materials like limestone, ensures stable supply and pricing.

Cement is highly versatile for builders, moldable into diverse shapes like curved roofs or flat slabs. Additives adjust its properties, such as faster setting for urgent repairs. Beyond construction, cement stabilizes soil for agriculture or mining. Cement benefits extend across industries, supporting global development. Its adaptability drives innovation in infrastructure projects.

Drawbacks and Environmental Impact

Cement production contributes significantly to environmental issues, emitting about 8% of global CO2. Heating kilns with fossil fuels and decomposing limestone release substantial carbon. These emissions make cement a significant contributor to climate change. Efforts to use alternative fuels are ongoing but face scalability challenges. Reducing cement’s carbon footprint remains a priority.

Cement drawbacks include health risks for workers and nearby communities. Cement dust can cause respiratory issues, including chronic conditions like silicosis. Wet cement is caustic, risking skin burns without proper handling. Safety measures, like masks and ventilation, are essential but not universally enforced. These risks highlight the need for stricter workplace protections.

Quarrying limestone for cement production disrupts ecosystems and water systems. The process consumes vast energy, often from non-renewable sources, increasing its environmental toll. Factory waste, such as kiln dust, can pollute soil if mismanaged. These impacts underscore the urgency of sustainable practices. Cement’s environmental cost must be addressed to balance its utility.

Innovations offer potential solutions to cement drawbacks. Low-carbon cements, using recycled materials or alternative binders, reduce emissions. Carbon capture systems could trap factory emissions, though adoption is limited. Blending cement with fly ash or slag lowers environmental impact. Scaling these technologies globally is critical as construction demand grows.

Leave a Reply