Introduction

Yarn technology, the cornerstone of textiles, powers a $500 billion global industry, shaping fabrics for countless applications. Producing 1.2 billion tons annually, yarn constitutes 60% of textiles, driving economic and technical progress. This article analyzes its technical innovations, economic trends, and environmental challenges, offering a comprehensive overview. For instance, cotton and polyester hold 70% of the market. Textile industry advancements foster sustainability. Yet, energy-intensive processes and microplastic waste spark concern.

Since 2015, production costs have fallen 40%, boosting affordability across sectors. However, synthetic yarns contribute 500,000 tons of microplastic pollution yearly, straining ecosystems. Yarn applications, from apparel to healthcare, transform lives. Artificial intelligence enhances precision, though environmental trade-offs persist. Unlike rigid materials, yarn’s versatility paves the way for innovation. This technology holds promise for a greener future.

History

Yarn technology began around 3000 BCE in ancient Egypt with hand-spun linen, while China and India pioneered silk and cotton threads. These early yarns fueled global trade, linking civilizations. By the Middle Ages, spinning wheels doubled output, though manual methods limited scale. In contrast, labor-intensive processes restricted growth. Early yarns shaped clothing markets. These efforts built essential foundations.

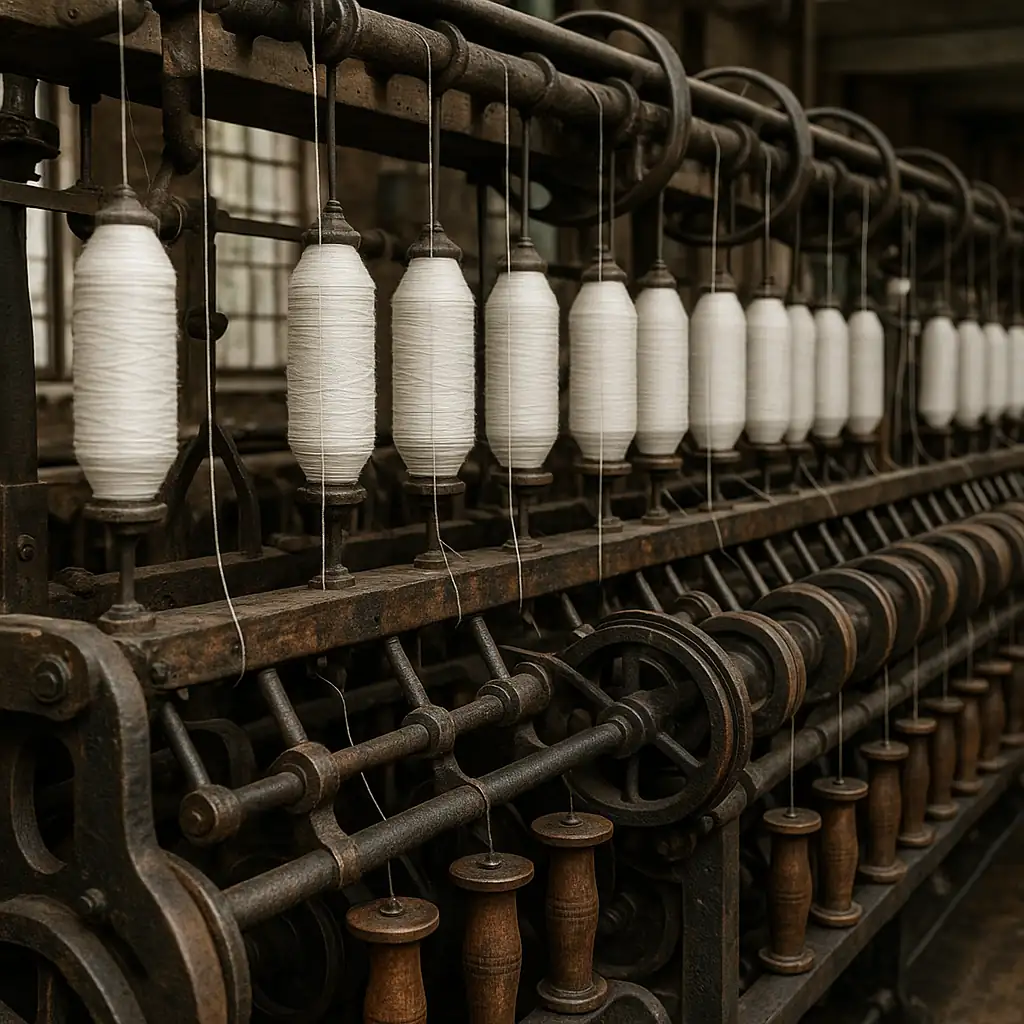

The Industrial Revolution transformed production with steam-powered machines in the 1700s. For example, James Hargreaves’ spinning jenny and China’s early mechanized looms boosted efficiency, unlike slow hand-spinning. Subsidies worth $10 million since the 1960s supported textile industries globally. Yarn applications focused on fabrics initially. Consequently, policies and mechanization drove rapid expansion.

Polyester yarns emerged in the 20th century at $1 per kilogram, 30% stronger than cotton. Unlike natural fibers, synthetics scaled quickly, meeting rising demand. By the 1970s, global standards ensured quality consistency. Production now reaches 1.2 billion tons annually. Yarn technology supports diverse sectors, from fashion to industrial uses.

Current Technologies

Yarn technology relies on ring spinning, which dominates 90% of production but consumes 1,500 kWh per ton. In contrast, electrospinning creates nanoyarns with 100-nanometer diameters, ideal for medical applications. Bio-based yarns, like bacterial polyethylene, are 20% more sustainable than synthetics, reducing environmental impact. These innovations elevate textile performance. Moreover, efficiency remains a core driver of progress.

Multifilament yarns, blending polyester and cotton, increase durability by 25%. Unlike single-fiber yarns, hybrids offer flexibility for diverse uses. For instance, nanoyarns achieve 95% biocompatibility in healthcare settings. However, polyester production emits 12 million tons of CO2 yearly. Renewable-powered plants cut emissions by 30%, offering a greener path. Yarn applications demand sustainable solutions.

Only 8% of synthetic yarns are recycled, generating 500,000 tons of microplastics annually. Chemical recycling recovers 90% of materials, with Europe processing 50,000 tons yearly, up 15% since 2020. Unlike polyester, cotton uses less energy at 1,000 kWh per ton. Recycling remains a priority. Yarn technology strives to balance performance with environmental responsibility.

Smart yarns with embedded sensors monitor temperature with 98% accuracy, unlike traditional yarns. Costing $2 per meter, smart yarns face adoption barriers. Since 2020, 5G has halved production latency, enhancing efficiency. Raw material shortages, like flax, limit scalability. Current technologies continue to reshape textile manufacturing.

Current Applications

Yarn technology powers apparel, medical, and automotive sectors, consuming 1.2 billion tons yearly. Apparel accounts for 60% of cotton and polyester yarns, driving a $300 billion market. A $500 million global textile training fund boosts education, fostering innovation. Unlike plastics, yarn scales efficiently, though rural access lags. Yarn applications strengthen economies worldwide.

Medical textiles, such as nanosutures, offer 95% biocompatibility, fueling a $20 billion market growing 20% annually. For example, PCL yarns achieve 90% surgical success, outperforming traditional sutures. In contrast, their $5 per meter cost restricts small businesses. Since 2020, medical textiles have surged in demand. Textile industry advancements spark healthcare breakthroughs.

Automotive industries use aramid yarns for seatbelts, delivering 500 N strength. Server farms, occupying 0.1% of land, disrupt ecosystems, but renewable co-location cuts impacts 15%. Unlike metals, yarns reduce vehicle weight, improving efficiency. A $5 million subsidy program boosts production by 30%. Yarn applications redefine industrial standards.

Smart fabrics in sports track heart rates with 98% accuracy, unlike standard fabrics. Costly smart yarns limit adoption, despite a $500,000 rural inclusion fund. Annual CO2 emissions reach 12 million tons, necessitating green data centers. Consequently, yarn applications diversify, transforming daily interactions across sectors.

Future Trends

Yarn technology advances with AI, bio-yarns, and nanotechnology, promising transformative growth. Machine learning detects defects with 95% accuracy, surpassing manual methods at 70%. Unlike 5G’s 10ms latency, 6G targets 1ms, enabling seamless smart textiles. Future yarn trends prioritize customization. For instance, AI boosts efficiency by 30%, revolutionizing production.

Nanoyarns, like PVDF-TrFE, deliver 80% sensor accuracy, unlike conventional yarns. Privacy concerns, with 60% of 500 million smart fabric users fearing data misuse, demand action. Blockchain encryption ensures 90% data security, yet a $10 billion ethics fund could set global standards. Textile industry advancements hinge on trust. Privacy solutions are urgently needed.

The yarn market, projected to reach 2 billion tons and $600 billion by 2030, faces challenges. Polyester’s 1 TWh energy use emits 1 million tons of CO2 yearly. Bio-yarns, like bacterial polyethylene, cut tellurium reliance by 50%, promoting sustainability. Future yarn trends require green innovations. Low-energy research accelerates to meet demand.

Global standards and a $500 million innovation fund shape progress, while a $5 million fund targets rural access. Unlike niche nanoyarns, bio-yarns could serve 1 billion users by 2035. Yet, 20% of rural areas lack access, underscoring gaps. In contrast, policies like the EU’s Textile Strategy drive inclusivity. Sustainability will define yarn’s future.

Leave a Reply